Duration: 4.5 months

Team

2 industrial design students

1 mechanical engineering student

1 automation and mechatronics engineering student

Team

2 industrial design students

1 mechanical engineering student

1 automation and mechatronics engineering student

The Challenge

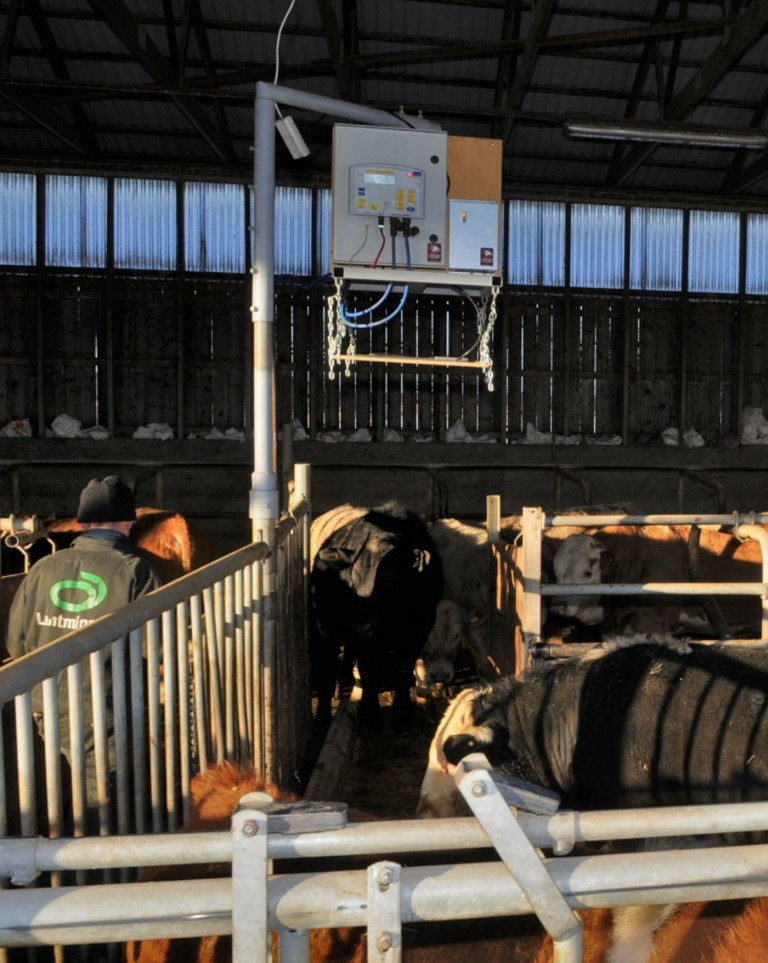

Hencol AB needed to find a solution for a diverse livestock weighing station suitable for most stables. Hencol's original "Hencol OPV" used RFID technology and load bars combined with a software to register each animal's weight when they passed through the station. Hencol saw a potential decreasing installation costs by making a quick-to-install station which didn't require special customization depending on the layout of the stable.

Hencol AB needed to find a solution for a diverse livestock weighing station suitable for most stables. Hencol's original "Hencol OPV" used RFID technology and load bars combined with a software to register each animal's weight when they passed through the station. Hencol saw a potential decreasing installation costs by making a quick-to-install station which didn't require special customization depending on the layout of the stable.

My responsibilities

- Designing qualitative research methods and analysing data

- Transcribing interviews

- Formulating needs

- Setting up concept generation sessions

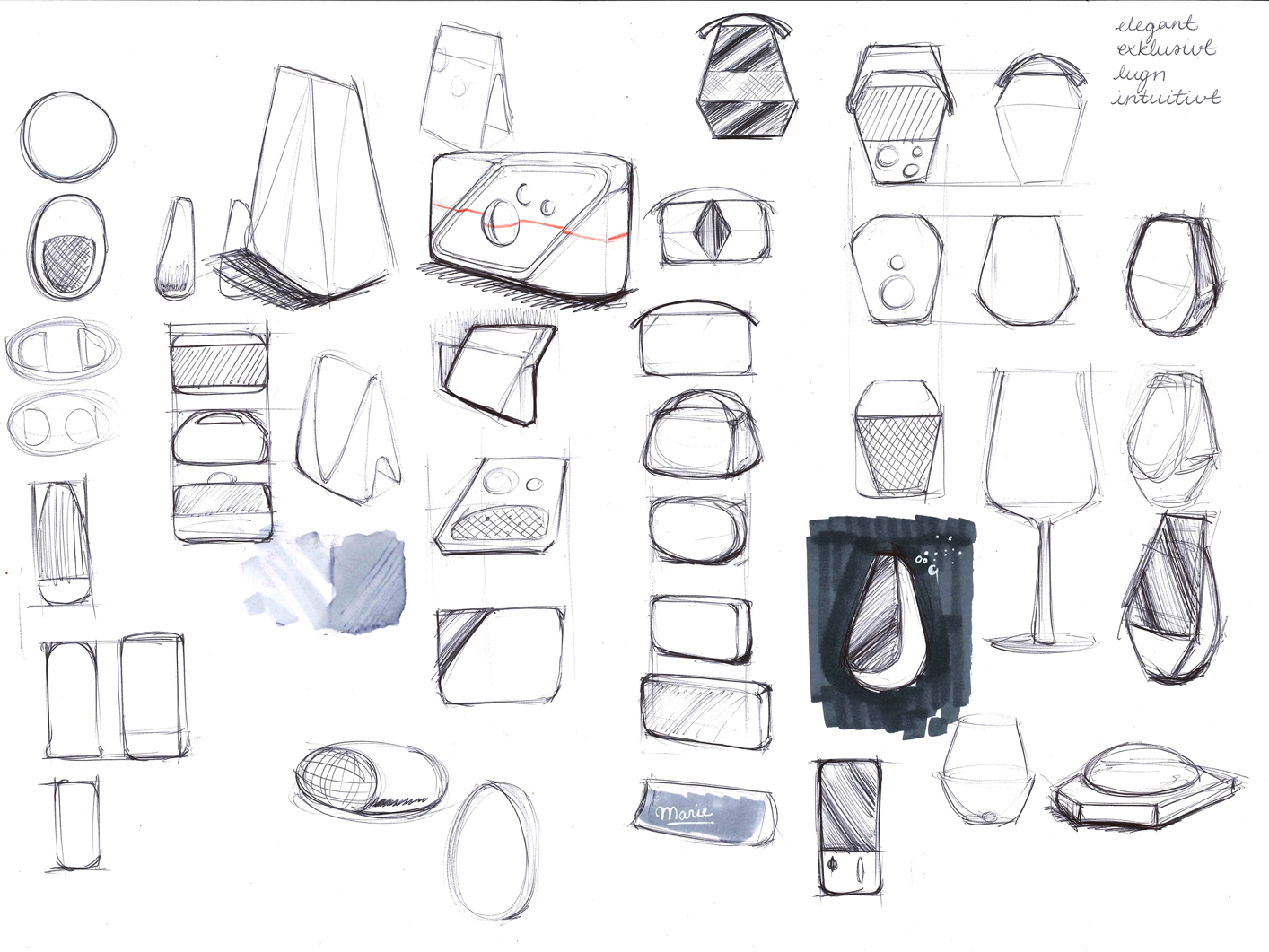

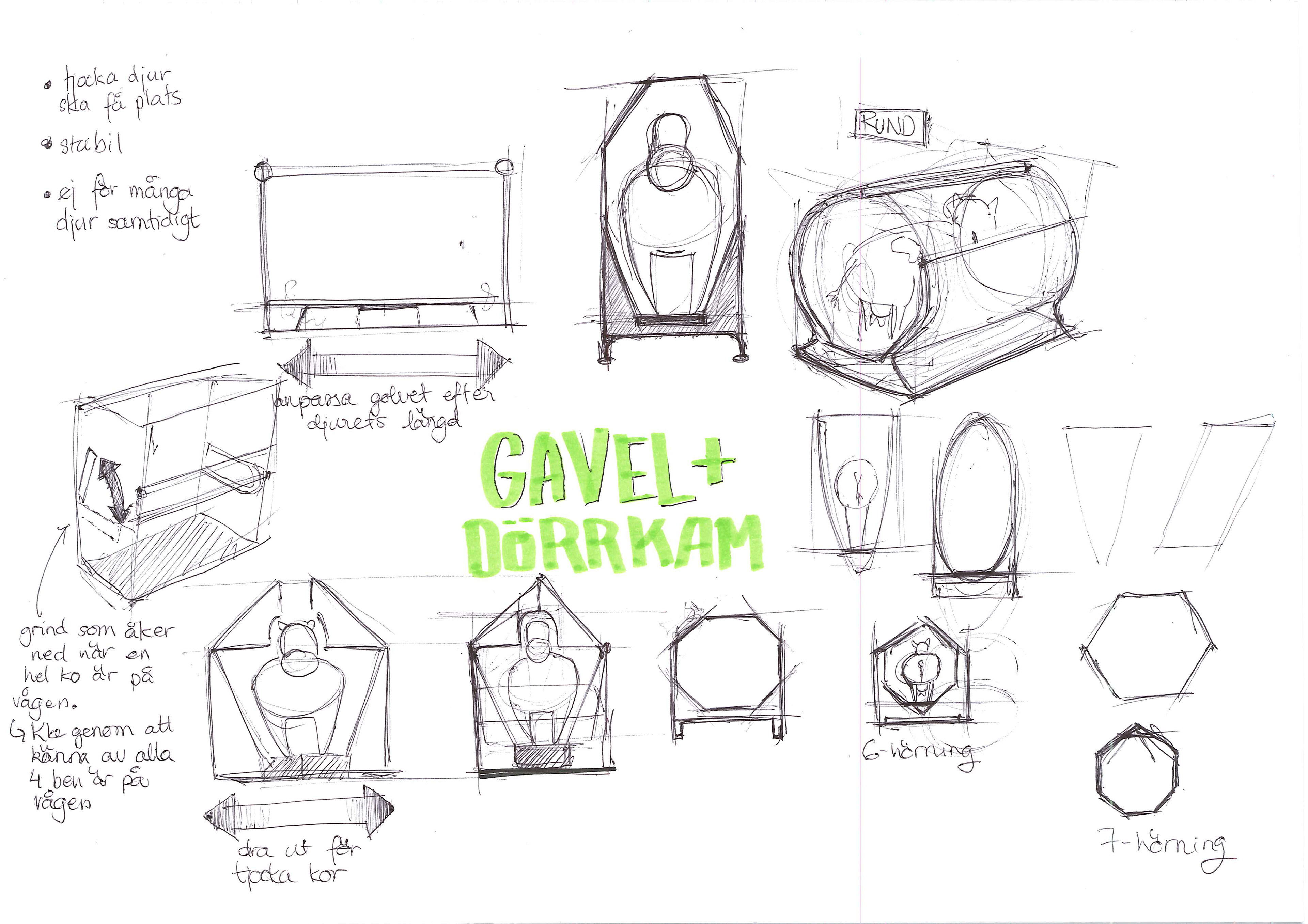

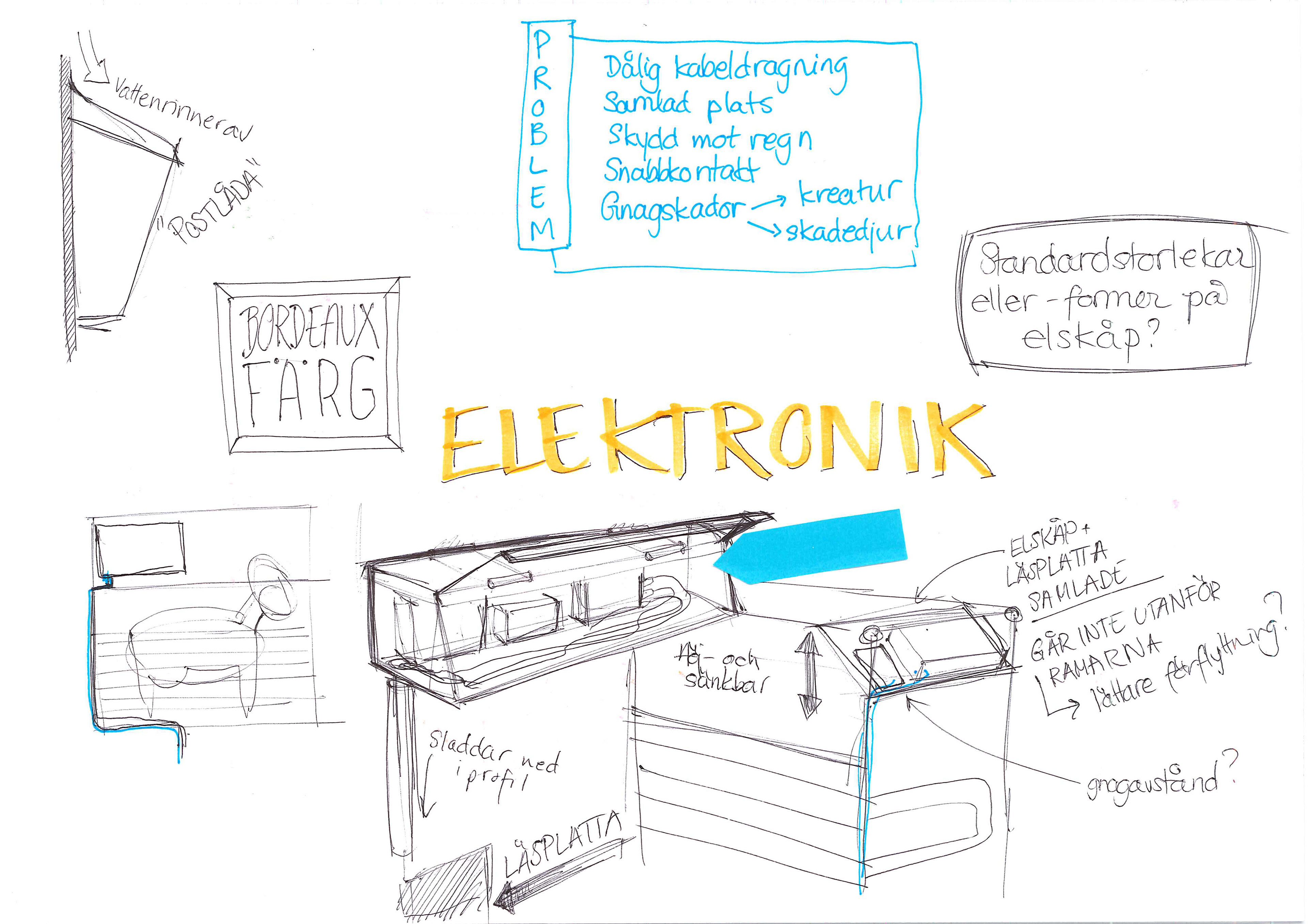

- Handsketching concepts

- Designing qualitative research methods and analysing data

- Transcribing interviews

- Formulating needs

- Setting up concept generation sessions

- Handsketching concepts

The Final Concept

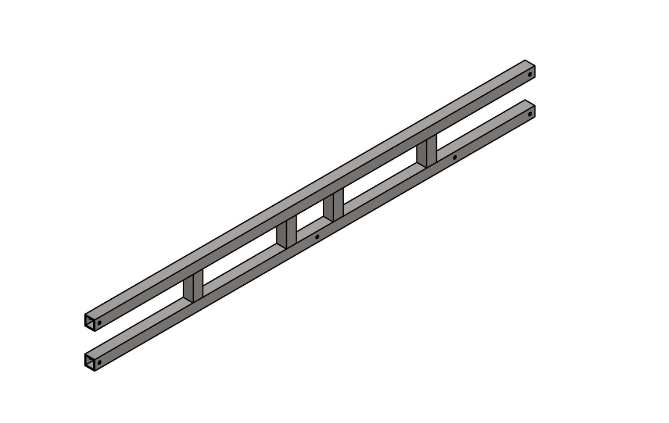

Hencol FLEX focuses on easy and quick assembly by pre-welding frames which can lie flat during transport to the farm. We wanted to please the needs of both farmers and cattle with a station that is durable, non-intimidating, easily cleaned, and can be transported with already existing tools in a farm.

Based on feedback from the collaborating company, we developed an initial concept called Hencol BAS, which was most similar to the original station. The biggest issue was to find a solution which allowed us to continue using the sensitive RFID-technology which was already used in previous stations and by farmers. Using non-conductive materials in places where the RFID-tech was most vulnerable fixed the problem.

Starting the project

We quickly understood that this would be an unusual project. Instead of one type of user, we had a second user who belonged to an entirely different species. Through literature studies, semi-structured observations and open questioned interviews we managed to empathize with both the farmers' and animals' wishes and concerns. At the end on the "Empathize and Define"-chapter you may find the found product requirements. Below you can see the three stables we visited.

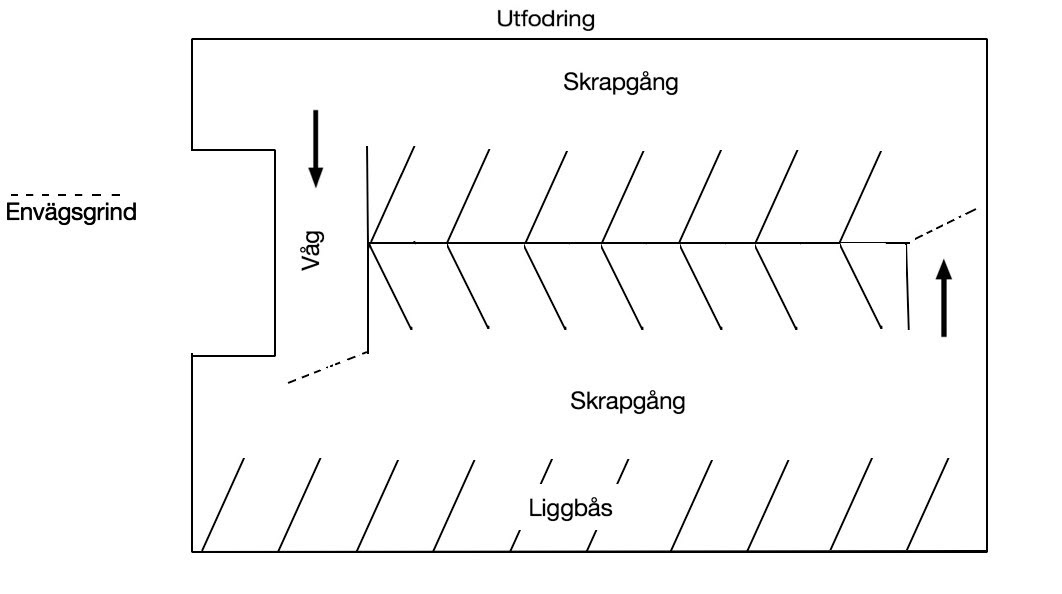

Stable 1 (S1) : 75 heifers, cubicle, walk-through weighing

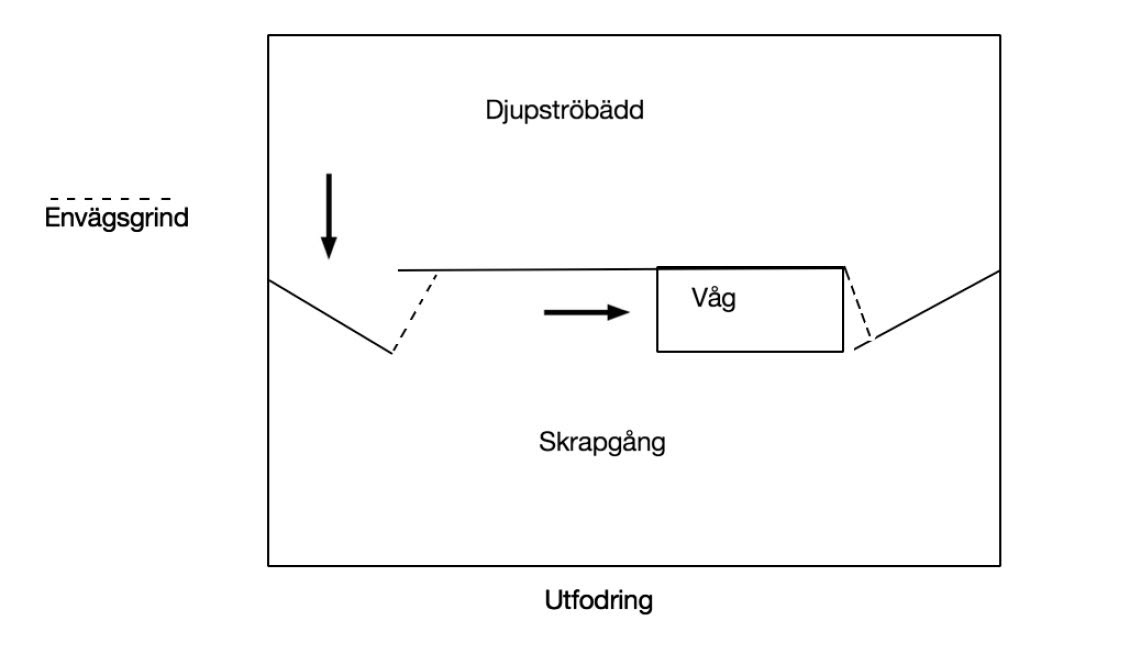

Stable 2 (S2) : 600 bulls, deep bedding stalls with scraper system, walk-through weighing

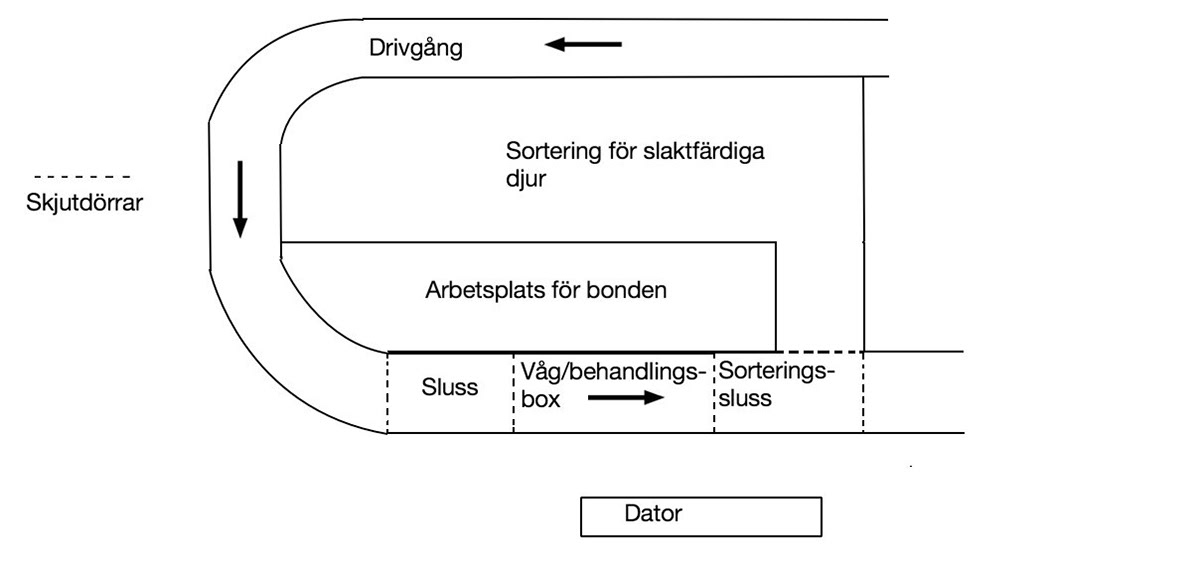

Stable 3 (S3) : XX bulls, bedding stalls, "herded" weighing

Stable 2 (S2) : 600 bulls, deep bedding stalls with scraper system, walk-through weighing

Stable 3 (S3) : XX bulls, bedding stalls, "herded" weighing

Animal behaviour

One of our first impressions were the stress levels at the stables. S1 had the calmest animals while S2 had a bit more brash animals. A reason could be that S2 only had bulls. S3 had the highest amount of stress, which was a consequence of a more invasive weighing method. High stress levels increased the risk of an animal trying to turn around in the station, slipping, and thus injuring itself, the farmer and/or damaging the weighing station.

One of our first impressions were the stress levels at the stables. S1 had the calmest animals while S2 had a bit more brash animals. A reason could be that S2 only had bulls. S3 had the highest amount of stress, which was a consequence of a more invasive weighing method. High stress levels increased the risk of an animal trying to turn around in the station, slipping, and thus injuring itself, the farmer and/or damaging the weighing station.

Identification

At S3 the RFID-antenna was placed at the top of the station, making it difficult to read the animal's ID-tag if they stressed through the station. This lead to extra work for the farmer who would need to manually enter the animal's ID-number.

At S3 the RFID-antenna was placed at the top of the station, making it difficult to read the animal's ID-tag if they stressed through the station. This lead to extra work for the farmer who would need to manually enter the animal's ID-number.

Unique Weighing stations &

Homemade modifications

Both observations and pictures from farmers show that each weighing station looked different. Each station had been customized for the specific stable which increases manufacturing costs. Even after Hencol installing the station, the farmers felt the need to modify it even more to fit their needs. They would drill holes or weld parts which of course affected the surface treatment and therefore increased the risk for corrosion.

Homemade modifications

Both observations and pictures from farmers show that each weighing station looked different. Each station had been customized for the specific stable which increases manufacturing costs. Even after Hencol installing the station, the farmers felt the need to modify it even more to fit their needs. They would drill holes or weld parts which of course affected the surface treatment and therefore increased the risk for corrosion.

long installation time

It normally took two days to both assemble the weighing station and install the software. The most time consuming was to put together the weigh bars with the rest of the construction. However, sometimes there would be miscommunication between the manufacturer and Hencol which increased the assembly time. A solution would might be to have a standard weigh station instead of customizing a station for each stable.

Faulty weights

There was an issue with the software registering incorrect weights. We saw animals only standing with their front legs in the station or getting into the station before the previous animal had completely exited. One could assume that the gate placement could affect how far ahead the animal stopped, as well as stress levels making animals walk too quickly through the station. We had to understand more about more about their psychology to properly address these issues.

There was an issue with the software registering incorrect weights. We saw animals only standing with their front legs in the station or getting into the station before the previous animal had completely exited. One could assume that the gate placement could affect how far ahead the animal stopped, as well as stress levels making animals walk too quickly through the station. We had to understand more about more about their psychology to properly address these issues.

Wear and tear

Cows are generally very curious animals and tend to explore with their mouth. They would gnaw on parts and get a good scratch by rubbing their body or head against the station. This meant that some parts had to be switched out after a while, which the farmer would prefer to do by themselves. The bottom part of the station was constantly exposed to dust, dirt and liquids which increased the risk for corrosion.

Cleaning

More than 5 kg of dirt on the weighing station would affect the weight registration. However, each stable had different cleaning routines which meant the dirt accumulation was a problem for only some farmers. S1 cleaned the stables every day and took the opportunity to hose down the station floor as well. S2 only cleaned the station once in a while but also had problems with faulty weight registrations. S3 would use air pressure to clean their weighing station every now and then, and would disassemble the whole station once a year for a deep clean.

Vulnerable cables

Since there was no standard station, cables were installed in unique ways at each stable. They were protected with a plastic tube which looked very temporary and could be perceived as unprofessional.

manufacturing

Hencol had up to 10 different subcontractors to create the customized stations. We believe this increased the risk of miscommunication and higher manufacturing costs.

Acceptance of autonomous weighing station

The agriculture industry is quite conservative and mostly farmers below the age of 50 who had an agriculture education were more accepting of using scales to decide when to send the animals to the slaughterhouse. Otherwise farmers trusted their eye estimation to estimate their animals' weights.

Since Hencol is visible at expositions and has won Elmia Lantbruk Innovation Award, the acceptance for autonomous weighing may increase. To facilitate acceptance, we thought farmers should perceive the station as robust, has a long life-span and is of high quality.

Product Requirements

From our data collection we formulated needs and wishes. The station should...

... allow size adjustment

... decrease installation time

... facilitate anchoring

... simplify manufacturing

... facilitate replacement of parts

... protect electronic components from animals and environment

... minimize dirt accumulation around scale

... minimize risk for stress

... allow size adjustment

... decrease installation time

... facilitate anchoring

... simplify manufacturing

... facilitate replacement of parts

... protect electronic components from animals and environment

... minimize dirt accumulation around scale

... minimize risk for stress

Ideate

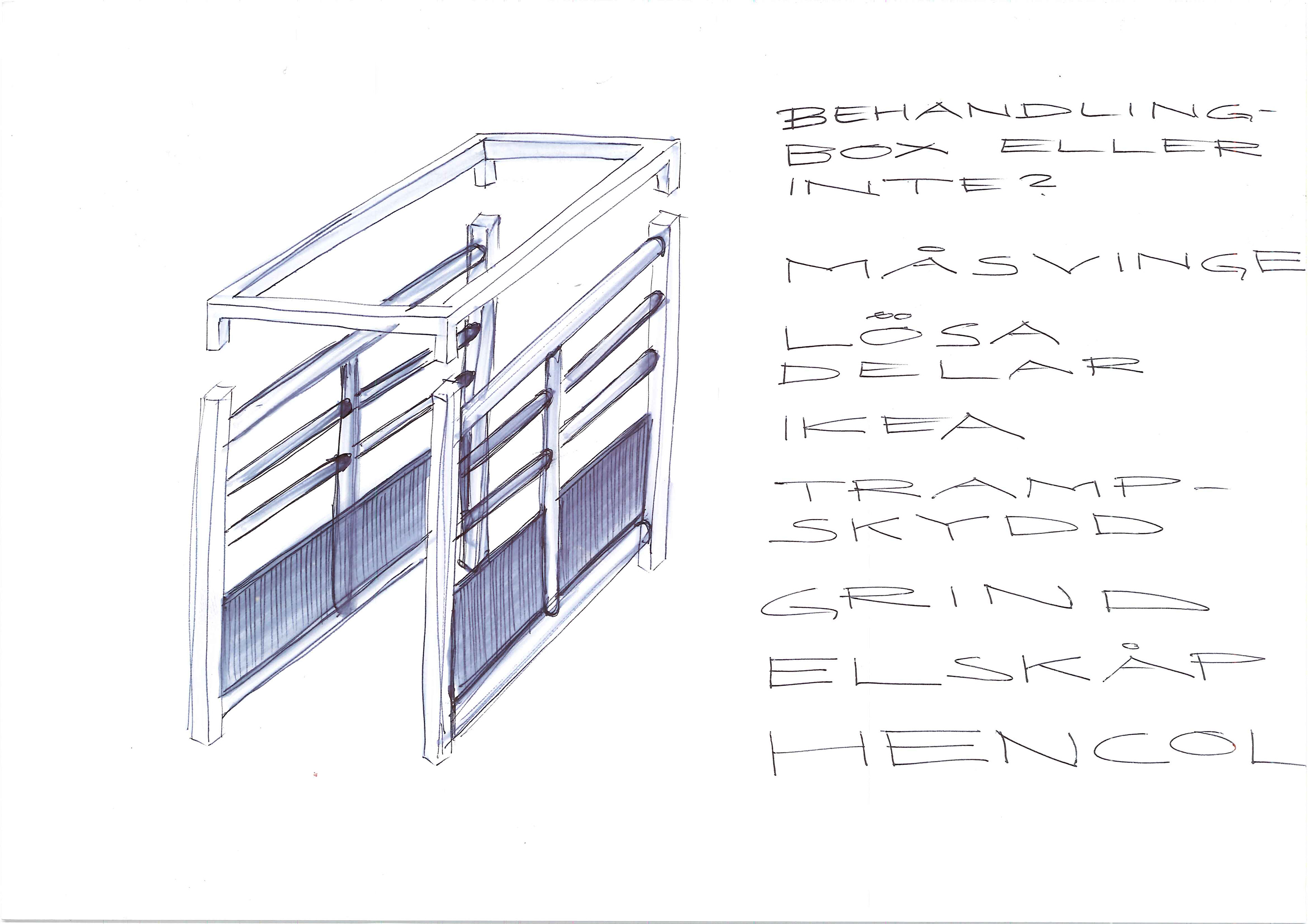

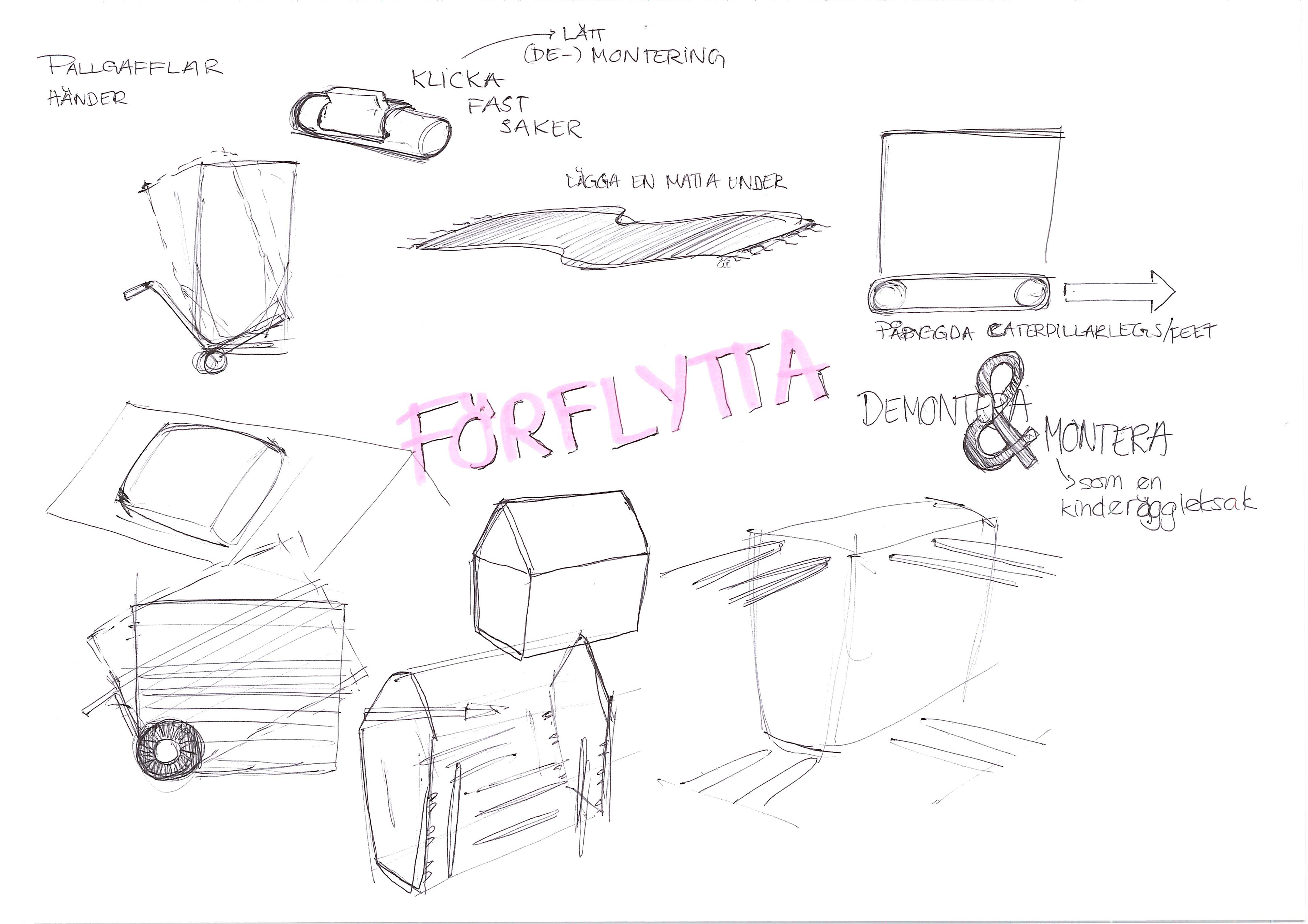

Based off of the functions and requirements we started the ideation process to optimize the weighing station Hencol OPV.

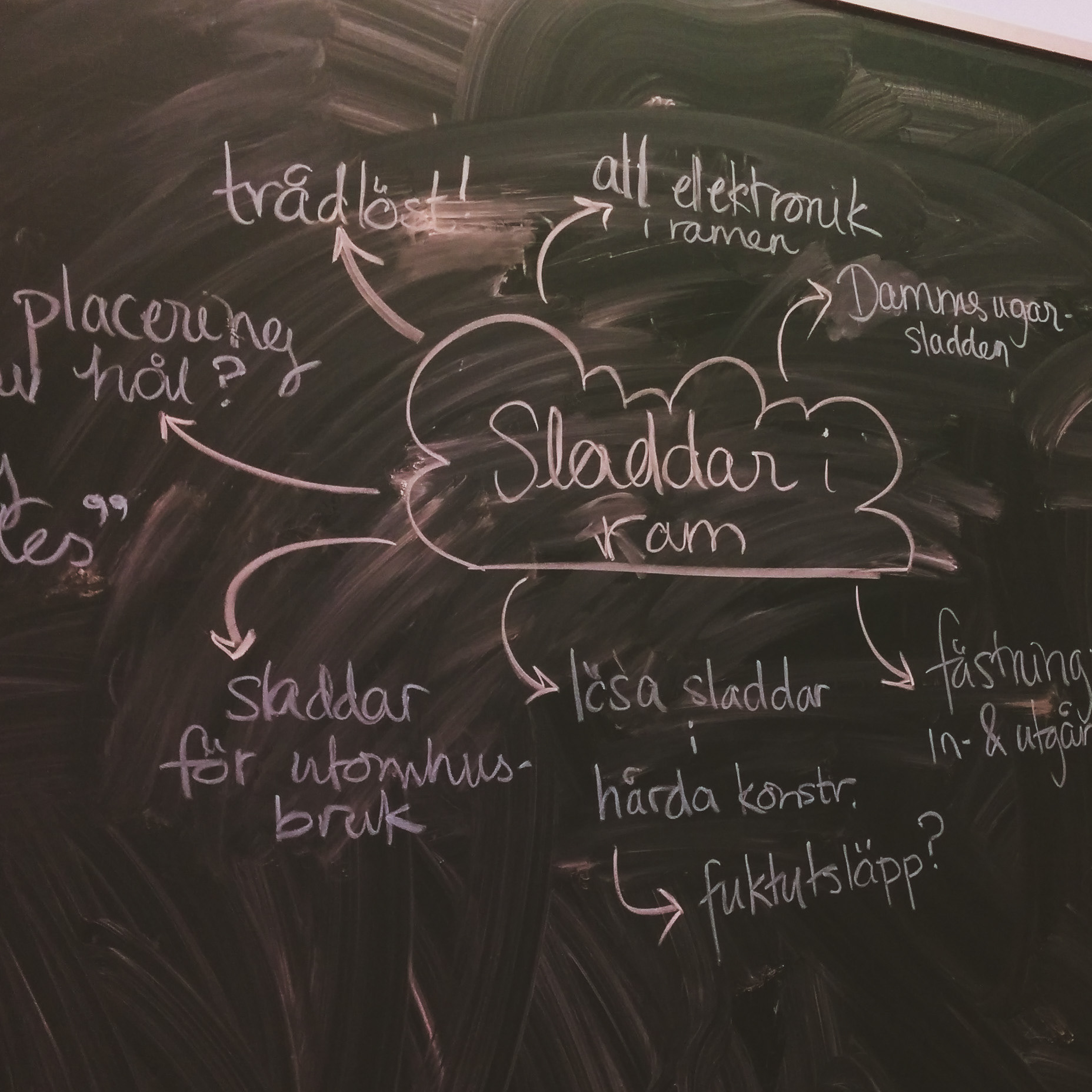

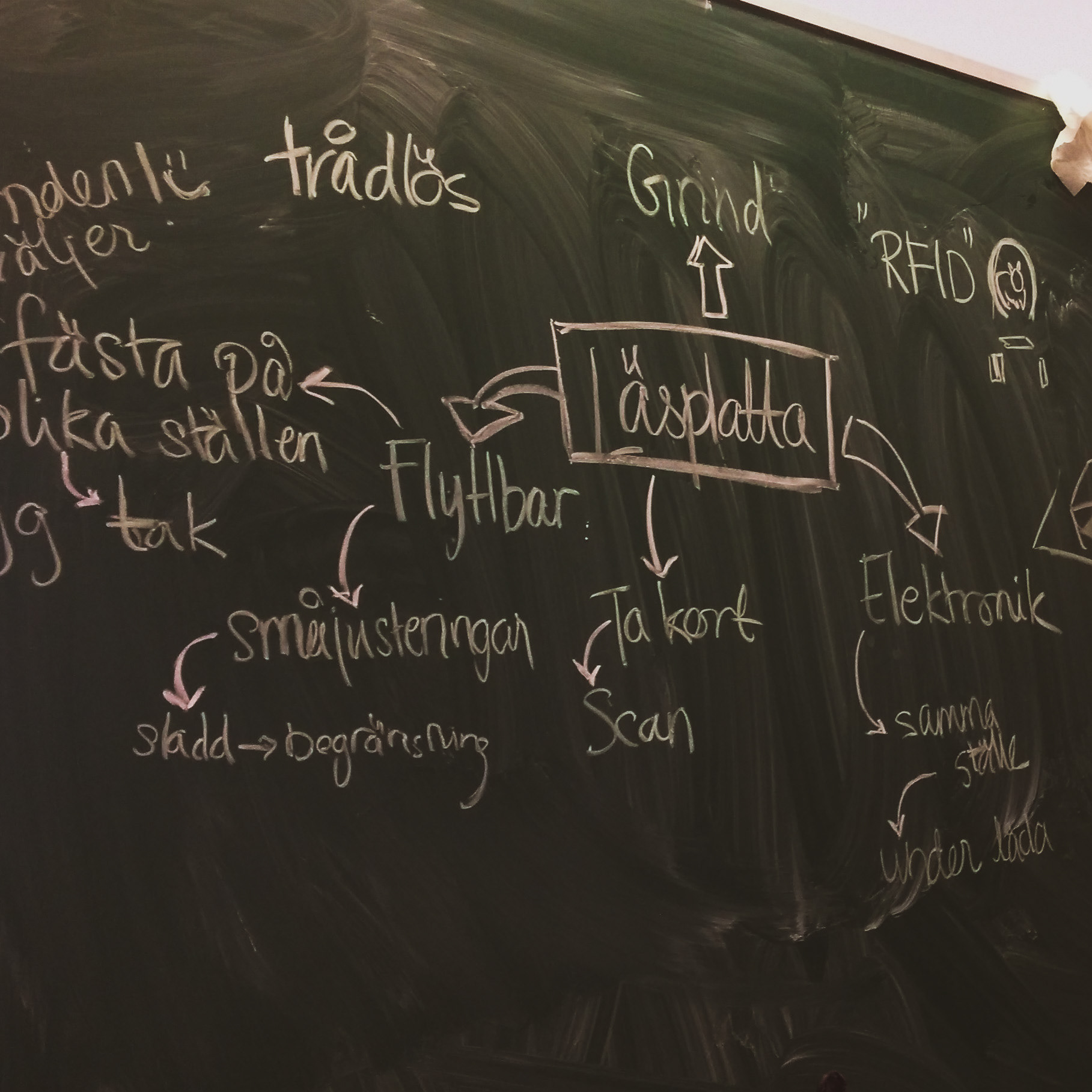

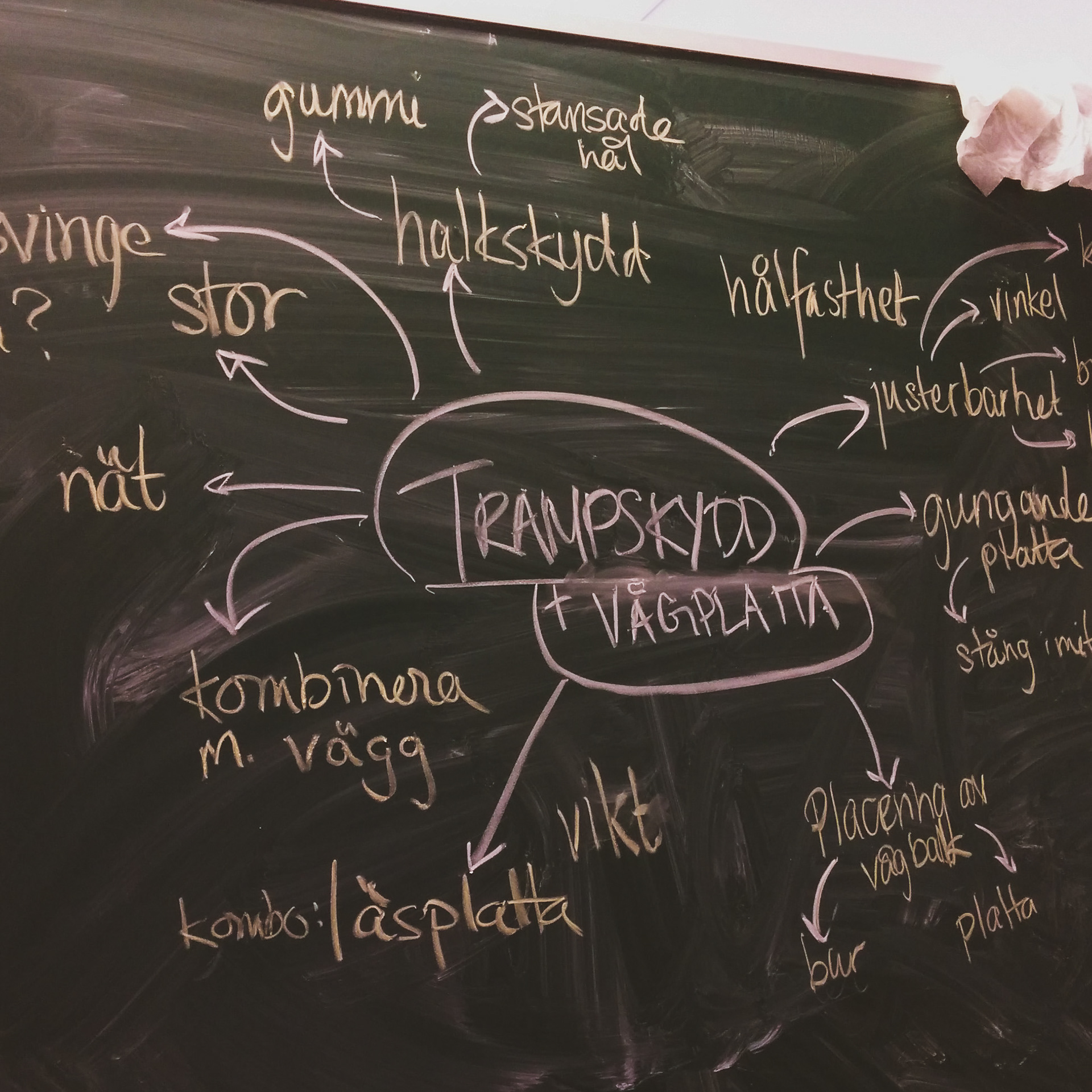

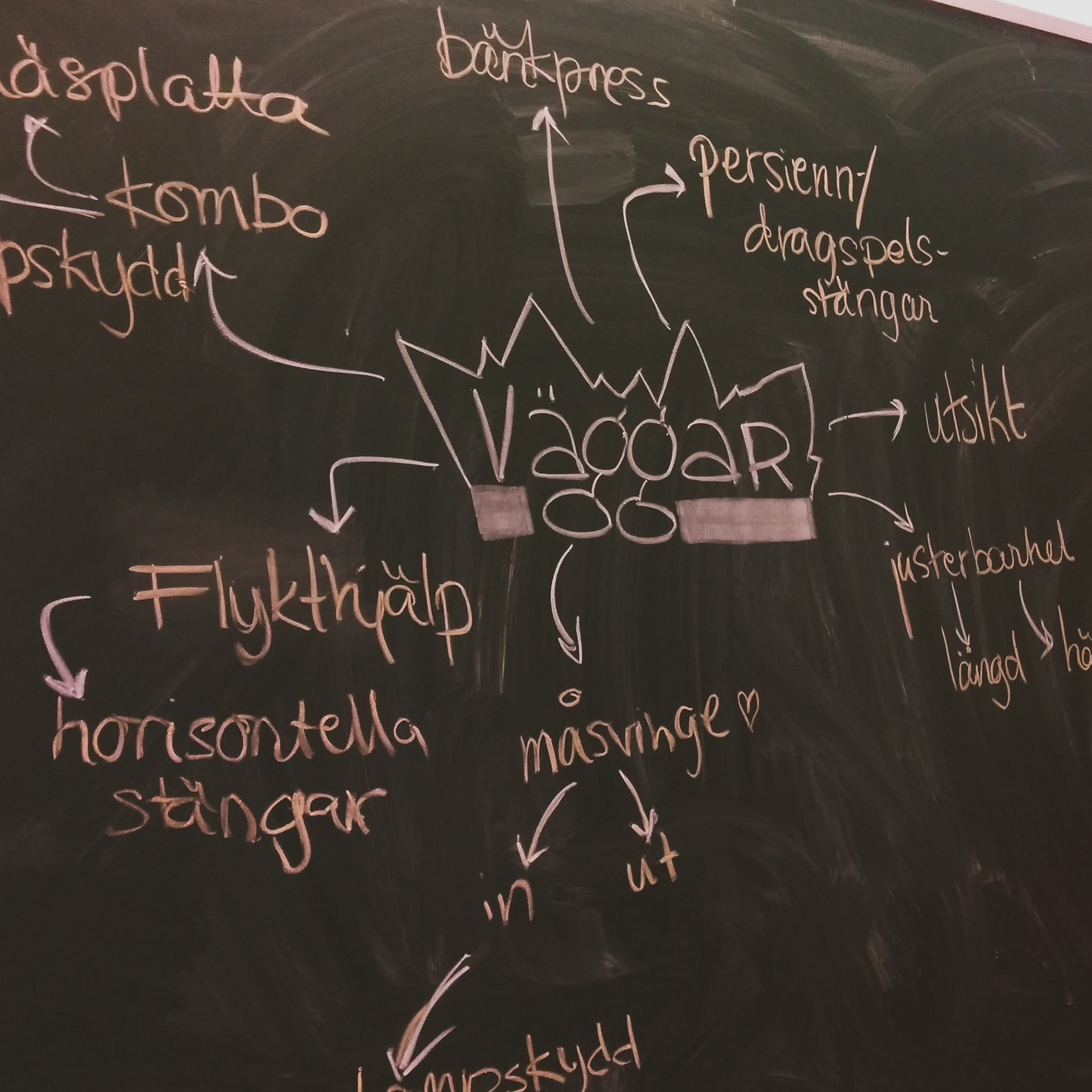

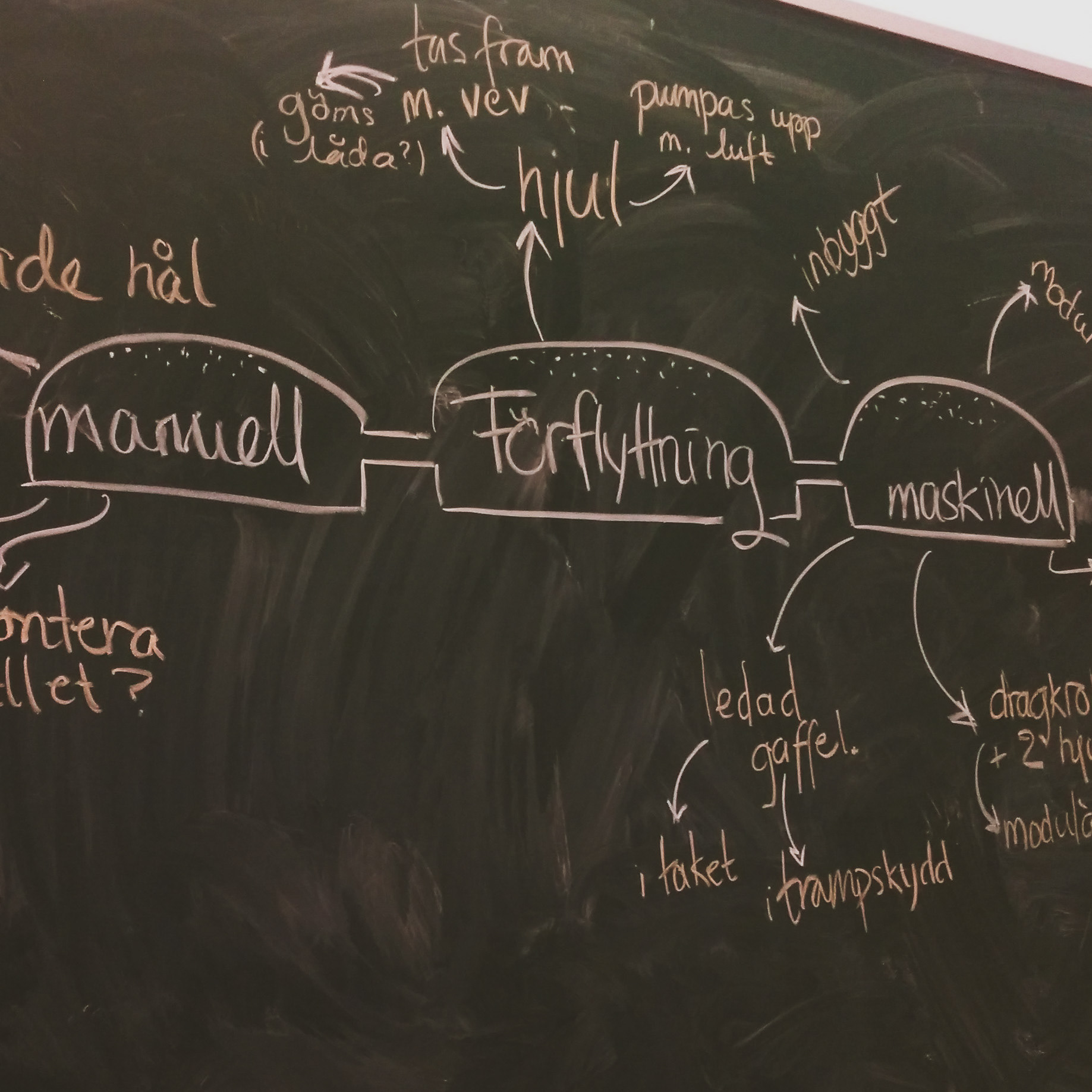

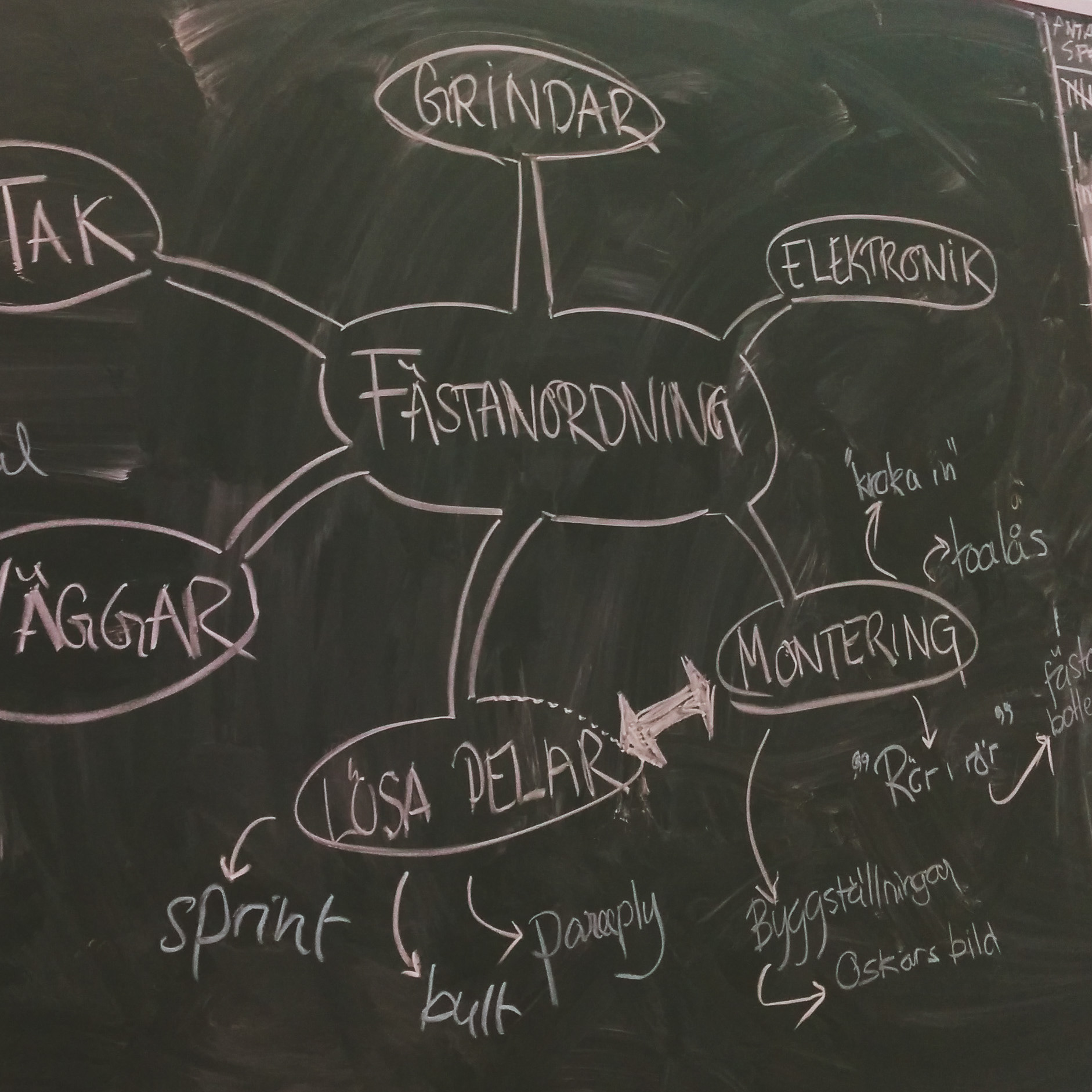

Brainstorming

We organized the brainstorming by generating ideas for one function at a time. There was always a high focus on positivity and helping each other developing ideas through discussion and sketching. The sketches förflytta, gavel and elektronik were mainly drawn by me.

We organized the brainstorming by generating ideas for one function at a time. There was always a high focus on positivity and helping each other developing ideas through discussion and sketching. The sketches förflytta, gavel and elektronik were mainly drawn by me.

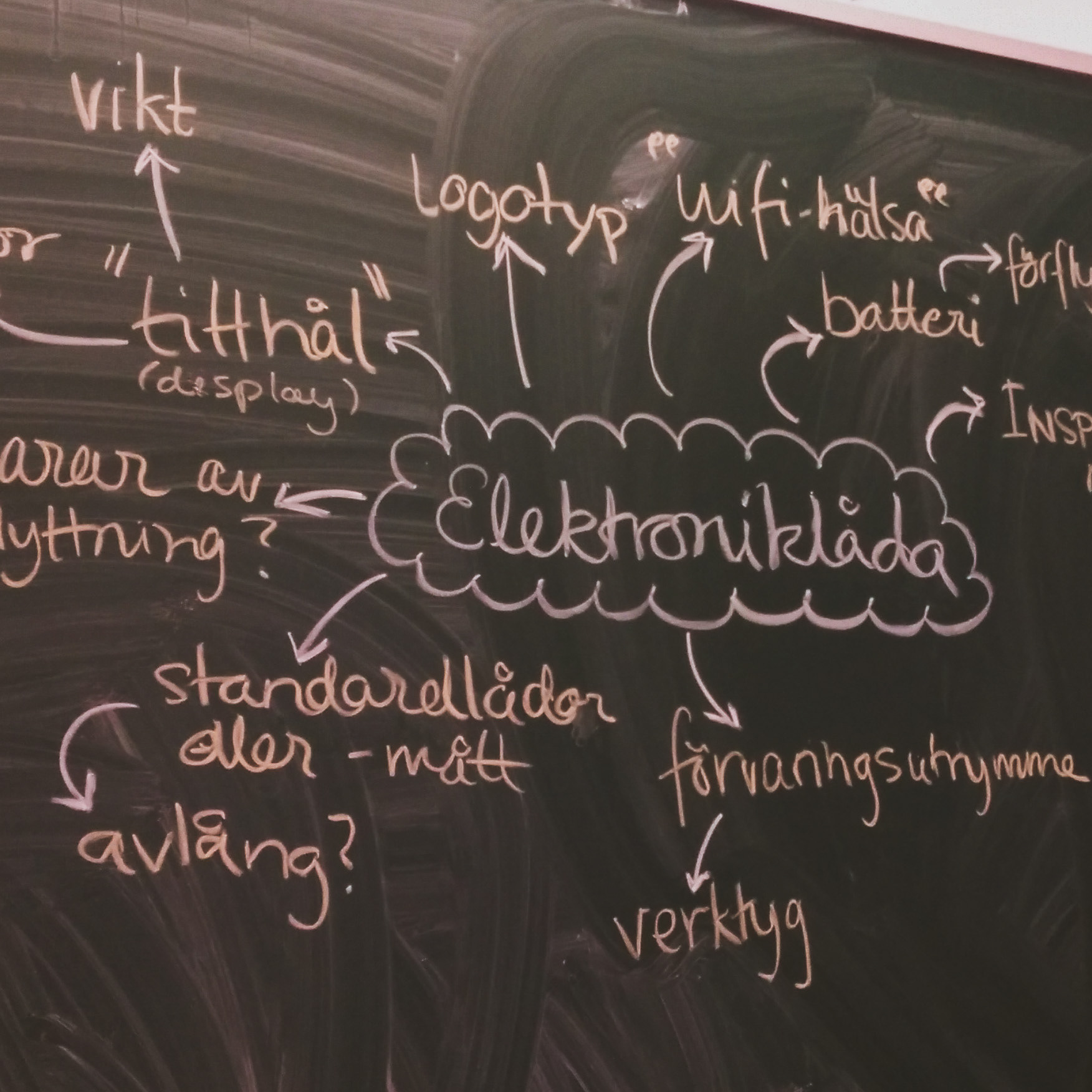

SCAMPER

A qualitative method to develop ideas from previous brainstorming session. For each idea we asked ourselves the same questions:

A qualitative method to develop ideas from previous brainstorming session. For each idea we asked ourselves the same questions:

Can it be replaced/combined/modified/used for something else/eliminated/etc.?

By treating each idea equally, we minimized the risk of details being missed or forgotten. I wrote the teams ideas on the blackboard.

lego-method

LEGO = Laborative Exploration Grading Optimization

LEGO = Laborative Exploration Grading Optimization

We hoped a physical model would help us compare ideas to the requirements as well as get us closer to a functioning model by exploring new ideas. Models such as this were very useful during discussions to clear any misunderstandings.

Concepts:

bas, multi & mini

bas, multi & mini

These concepts were presented to Hencol and an external product developer who was a partner with Hencol.

I drew the sketches for Hencol BAS and Hencol MINI.

Hencol BAS

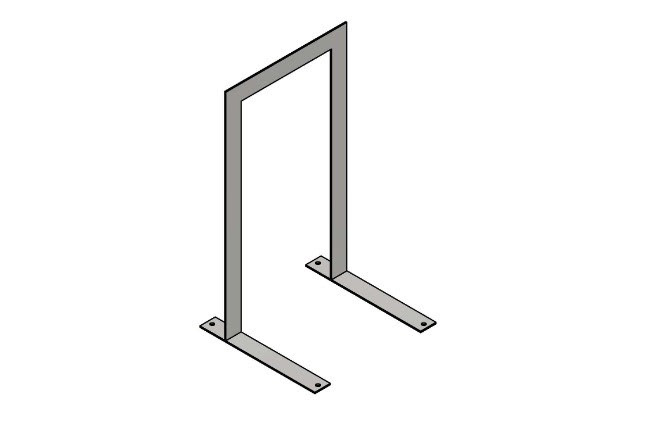

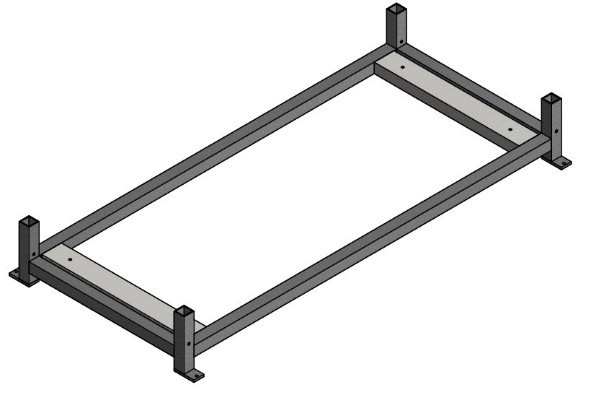

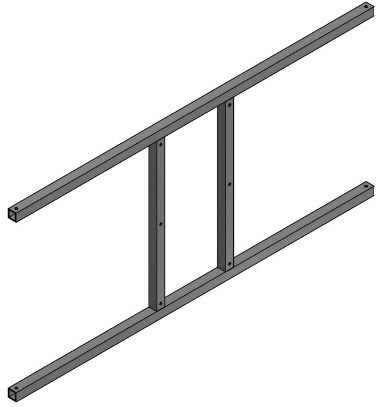

For Hencol BAS we focused on simplifying the assembly. When the package arrives to the farmer, the bottom-, side-, and top frame are already welded separately into four frames which would be bolted together at the farm.

For Hencol BAS we focused on simplifying the assembly. When the package arrives to the farmer, the bottom-, side-, and top frame are already welded separately into four frames which would be bolted together at the farm.

CON: This concept focuses more on improving the current station model and therefore may seem too "timid" for a new concept.

Hencol BAS has a one-way gate which can be adjusted both horizontally and vertically to ease the cattles minds when passing through. An adjustable gate may prevent faulty weights by making it more welcoming to open and pass through the gate.

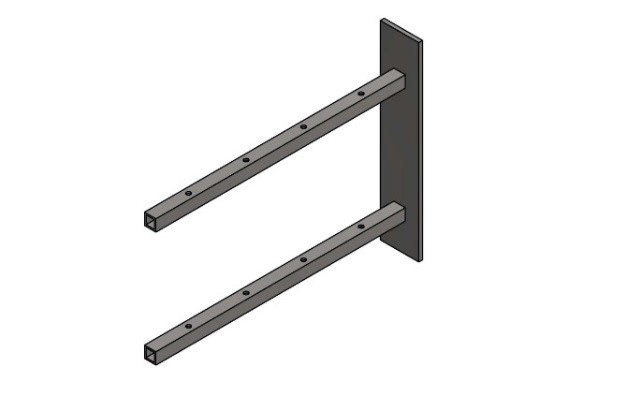

For a simplified assembly, bottom and gables would be welded beforehand so that mostly only bolts would be necessary to assemble Hencol BAS at the farm.

A couple poles have been reinforced with short vertical rodes to allow forklifts to move the station. Shown in the drawing to the left/above.

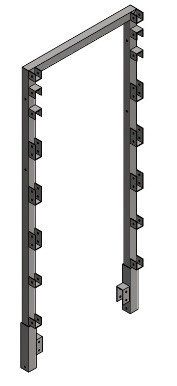

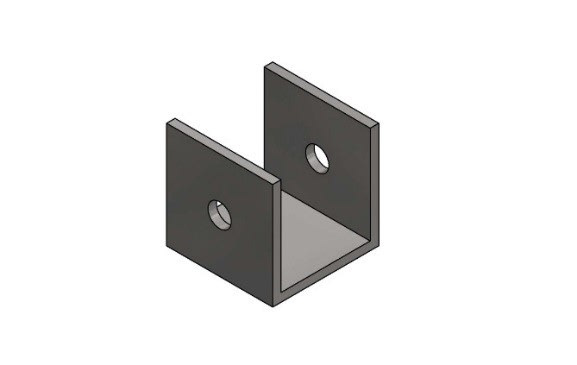

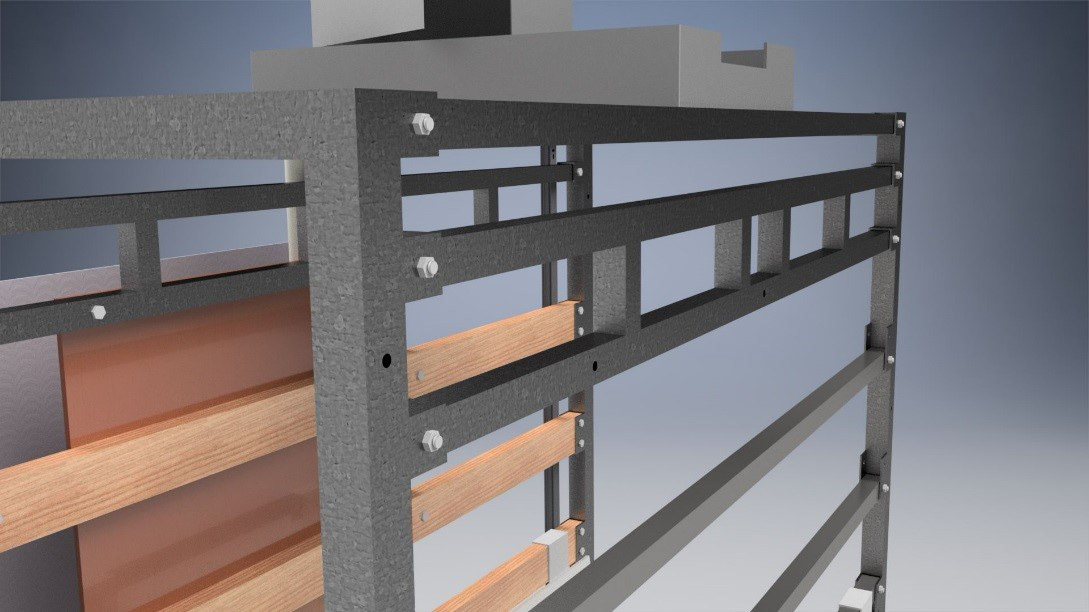

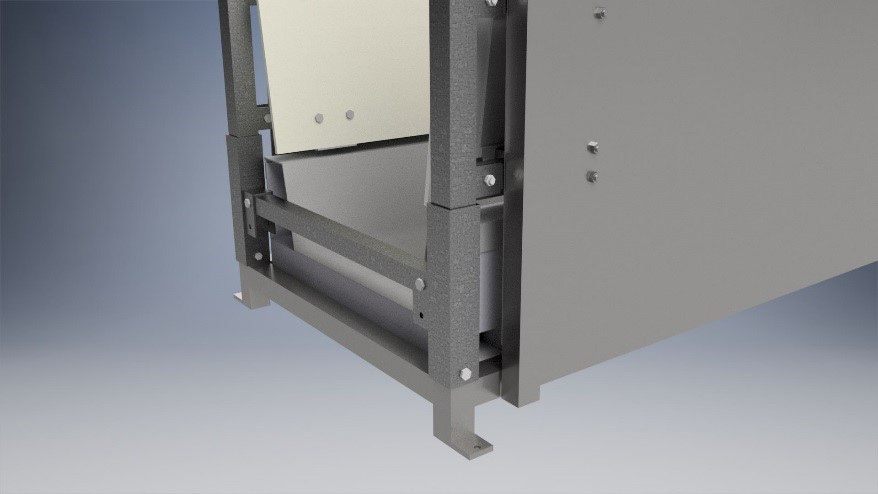

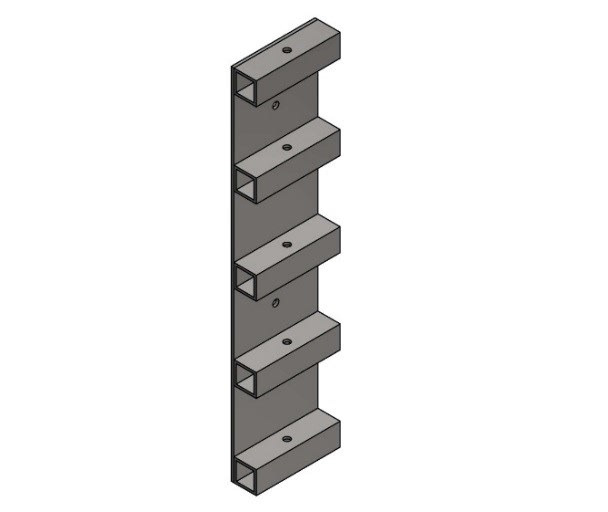

U-attachments make it easy for assembly and also strengthens the station when used. These attachments are used for other concepts as well.

The electricity cabinet is put down low to facilitate placing the station and access to the cabinet can be achieved since the ceiling can be opened. It has hinges and is locked in place with shootbolts. There are also lights in place to signal when a weight is registered or when there is a system error.

Along the sides are V-shaped walls (slip protection) to stop animals from accidentally getting caught with their legs between the poles. The V-shape stops the animal from turning around.

HEncol Multi

This concept was created to be adjustable according to the needs of the farmer and the size of the cattle. Since both the layout of the farm and the size of the cattle vary between different farmers - we thought it would be suitable with something easily adjustable.

This concept was created to be adjustable according to the needs of the farmer and the size of the cattle. Since both the layout of the farm and the size of the cattle vary between different farmers - we thought it would be suitable with something easily adjustable.

CON: With so many movable parts, it may impose a higher risk of both damage to the station and injuries among curious cattle.

The bottom frame and side frames are welded individually. One wall is bolted permanently to the bottom frame while the opposite wall can be adjusted into 3-4 positions to facilitate weighing different sized animals. A bolt or shootbolt will keep the wall in place.

We also applied the same type of slip protection here as in Hencol BAS, but with a part that moves with the rest of the wall.

The walls are built with U-attachments the same way as Hencol BAS.

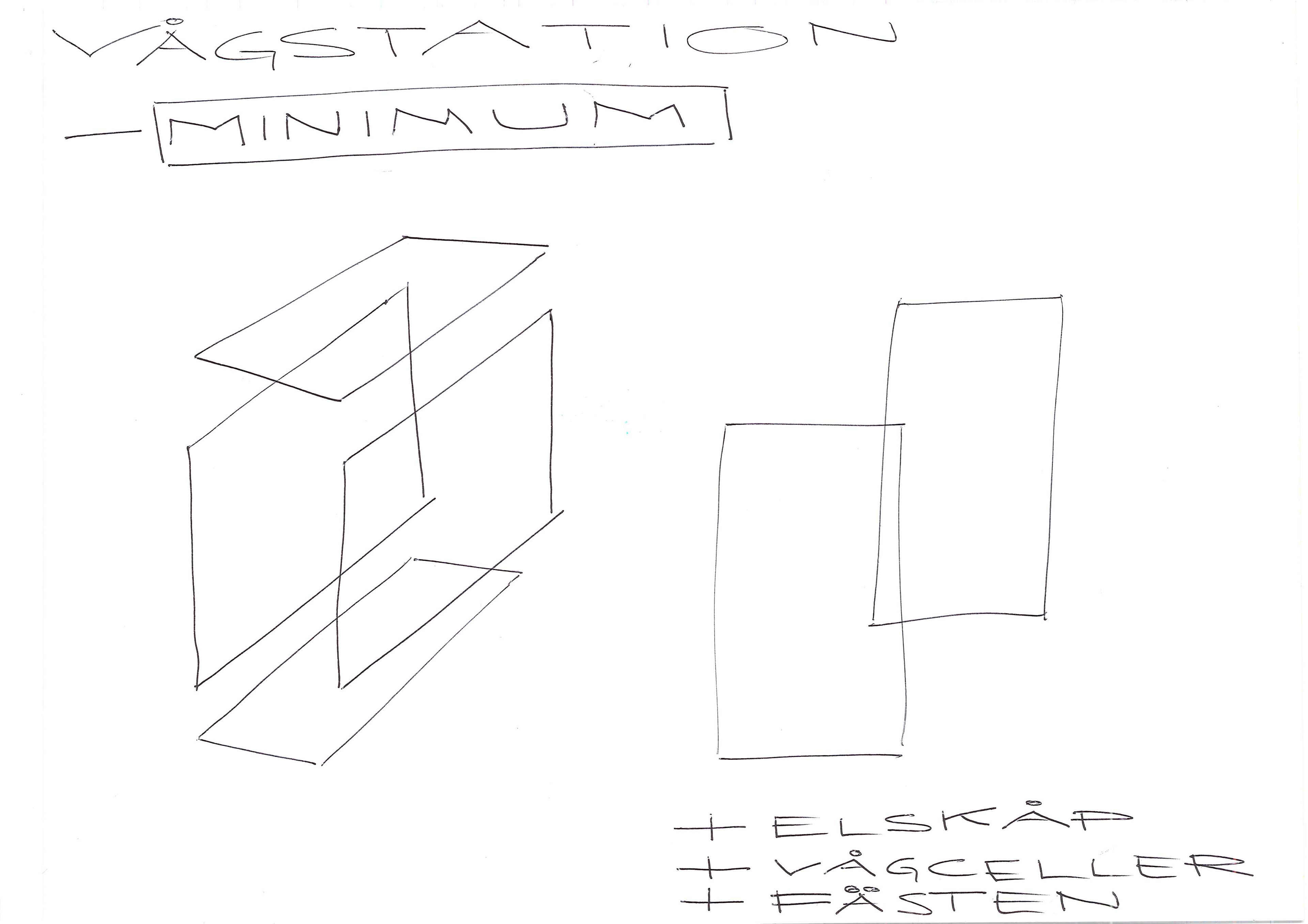

Hencol Mini

For this concept, the idea was to find a the minimum solution that would fulfill both the farmer's and cattle's needs.

For this concept, the idea was to find a the minimum solution that would fulfill both the farmer's and cattle's needs.

CON: Animals could easily jump out of the station.

The frame is pre-welded and is fully assembled with scale and walls at the farm upon delivery. The walls are attached with hinges to the frame and can be moved into 3 different positions to create a slimmer passage to avoid animals turning and also to be slip protection.

With a more minimalistic approach, we get a lighter station that is could easily be moved around as pleased around the farm. The is especially beneficial if the cattle is divided into different areas.

The gate uses the same solution as previous concepts where it can be adjusted both horizontally and vertically.

Feedback

The feedback meetings gave us vital information useful to proceed. Hencol told us about the limitations of the RFID-technology which wasn't allowed to be close to metal (25 cm away from it) and also had a cord at a magical fixed length of 80 cm. Now, Hencol BAS, MULTI and MINI all had metal poles and slip protection as well as a distance from the RFID-antenna to the electricity box greater than 80 cm. We had to scrap most of the concepts.

The feedback meetings gave us vital information useful to proceed. Hencol told us about the limitations of the RFID-technology which wasn't allowed to be close to metal (25 cm away from it) and also had a cord at a magical fixed length of 80 cm. Now, Hencol BAS, MULTI and MINI all had metal poles and slip protection as well as a distance from the RFID-antenna to the electricity box greater than 80 cm. We had to scrap most of the concepts.

Hencol also asked for a simple construction with few moving parts since it would be less of a risk to manufacture and sell. They wanted to focus on easy assembly and manufacturing.

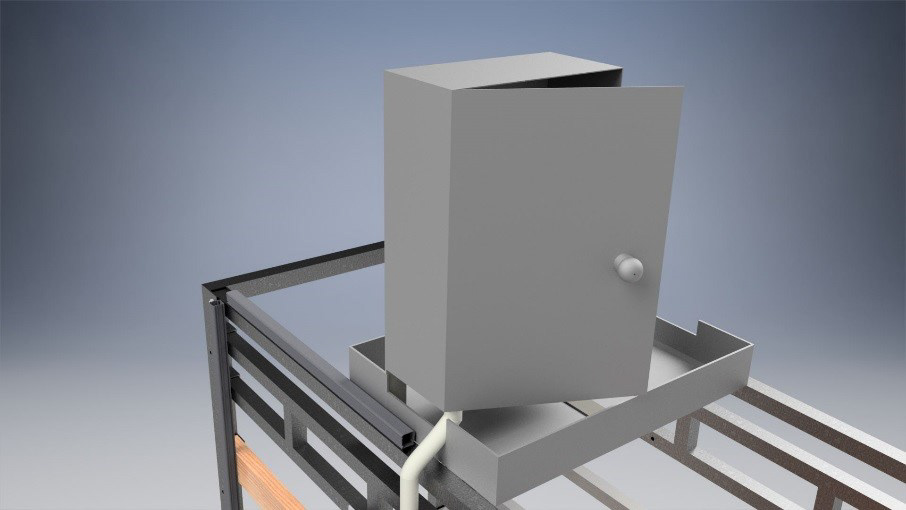

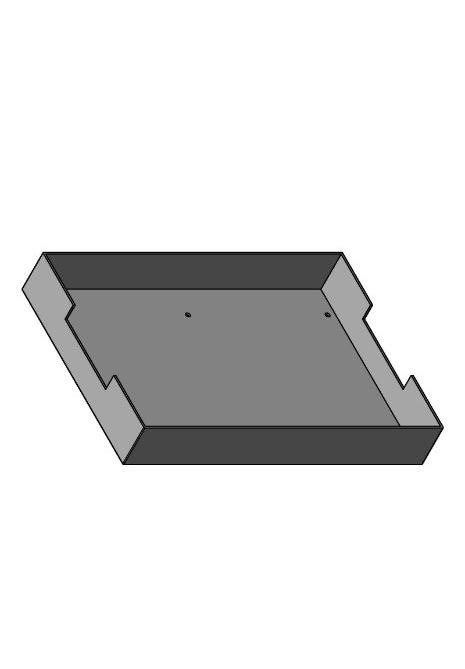

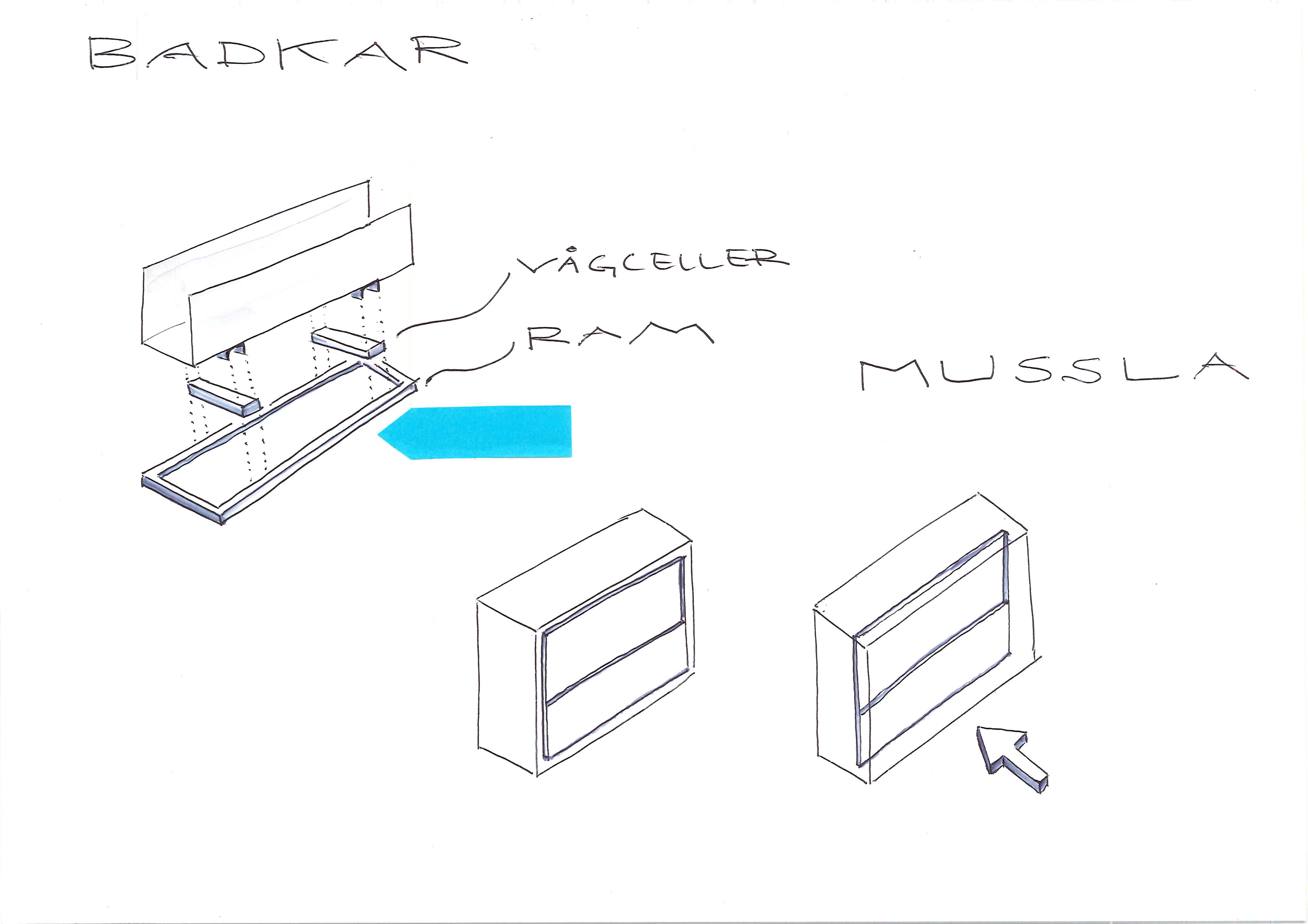

Hencol FLEX Details

ADJUSTABLE SETUP

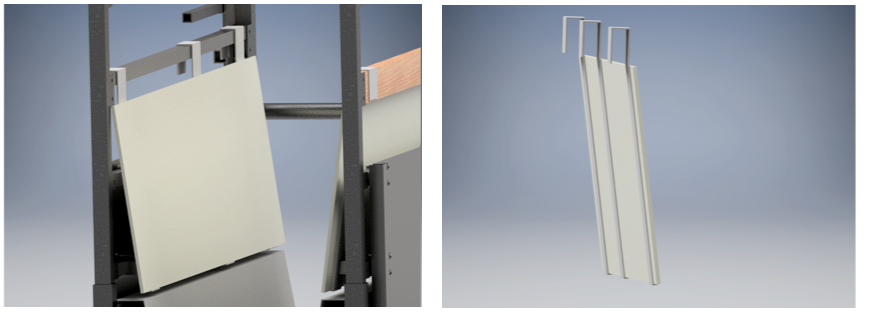

The station is delivered with pre-welded door frames, bottom frame and roof. Side beams are bolted into place in the U-attachments. As stable layouts are very different, we wanted the farmer to be able to choose whichever side was most suitable to place the RFID-antenna, gate, etc.

transportation

For transport with machine (forklift), steel beams have been reinforced with short vertical profiles which decreases the risk of deformation. The beams are placed high up to ensure that it wont be tipped over when lifted. Also the U-attachments are turned upside down to decrease the amount of pressure on the bolt when transported.

CLEANLINESS

After the floor and load bars have been installed, the slip protection is hooked onto the steel beams and is bolted into place. There is enough space to clean between the wall and protection when needed.

AVOID FAULTY WEIGHTS

We added a steel bar as a threshold to make walking into the station an active action by the animal. Hopefully we can avoid a second animal going through the station before the first one has exited which would lead to less wrongfully registered weights in the system. The threshold can be adjusted in two heights with upside down (to avoid sharp edges) U-attachments.

A gate stops the animal from walking in from the wrong direction and also helps avoid faulty registered weights. The gate can be position in four positions horizontally and three positions vertically by using the module to the left. Where depends on the animals' average wither. A horizontal adjustment could be useful to avoid the animal feeling intimidated by the gate since they have a need to see "the light at the end of the tunnel" (without sounding too sinister). The gate itself is a standard product since earlier. We added a gate-stop to make sure the gate stays in place when closed and doesn't create unnecessary and disturbing noises when it is being opened and closed.

SAFE PLACEMENT

The electricity cabinet is bolted onto a metal tray, on top of the station, to protect the electronic components from animals. It can be placed in 6 different positions depending on the layout of the stable.

Most cords leading up to the electricty cabinet are protected with metal cable trays, however, the RFID-cord is protected with a plastic tube to avoid disturbances in the RFID-technology.